PRODUCT DESCRIPTION

LeadClear is a premium performing, translucent, matte finish, water-based, ultra low VOC, non toxic, modified acrylic coating designed to permanently abate lead paint via encapsulation as per ASTM E1795 requirements. LeadClear is specifically formulated to adhere impeccably to existing coatings while preserving the aesthetics of the components & areas its being applied to such as walls, moldings, baseboards, stair stringers, posts, frames, etc. that require lead abatement.

Unlike other lead paint encapsulates which are applied thick & pasty; LeadClear goes on smooth,”milky white” & dries translucent; thus maintaining all existing colors & look while making applied areas lead safe.

TYPE: Water-based acrylic

FINISH: Matte

Color: Milky white (wet) Translucent (dry)

Mixable with other products: no

Paintable: yes

Sizes: 1, 5-US gallon containers

Disposal: in accordance with local, state & federal regulations

Application Equipment: airless spray, brush, roller

Mixing: ready to use, mix thoroughly

Drying Time: 2 to 6 hours to touch depending on ambient temperature

Full Cure: 11-15 days depending on ambient temperature

VOC: <195 g/l

Clean up: soapy water

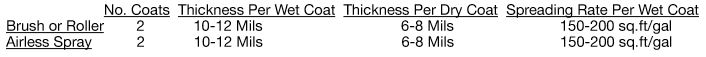

Spreading Rate to Achieve Required 12-14 Mils Dry Film Thickness

Spreading Rate to Achieve Required Dry Film Thickness – 50 sq.ft/gal

Note: Spreading rate does not include any loss during application process.

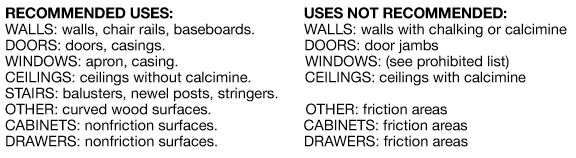

PROHIBITED: floors, stair treads, thresholds, as well as the sashes, parting bead‘s, window wells, and the interior/exterior or header stops of movable windows.

SURFACE PREPARATION: All surfaces must be clean, sound, dry & free of dust, rust, grease, oil, mildew & loose particles before application. A licensed deleader must remove all flaking and peeling paint down to a sound surface. Repair damage with a joint compound and smooth over with a damp sponge to remove excess compound and blend into surrounding wall surface. Remove all oil, grease, wax, smoke residues and other contaminants by washing with a suitable cleaner and rinsing with clean water. Remove mildew by washing with a solution of TSP (tri-sodium phosphate) in 1 gallon of water and add 1 quart of commercial bleach. Wear gloves and protective eyewear if using bleach solutions. For high-gloss surfaces, wet scour with TSP or a strong detergent substitute and water solution using course steel wool to eliminate any gloss. Thoroughly remove by washing any residual scouring material, detergent or other surface preparation material, and dry completely prior to application. Although no special primers are required, there may be occasions where primer would be beneficial in the overall performance of the coating. Prime water stains with stain blocking primer, prime chalking with penetrating chalk primer, prime bare wood within a enamel undercoater; prime drywall with a quality acrylic primer & sealer.

ENCAPSULANT APPLICATION: Apply in the multiple coats to achieve total thickness of 20 mils (wet). Use a wet mil gauge when applying product. Do not apply if ambient temperature is below 45°F. Airless spray application in two costs (each 10-12 mills) is recommended for best results, including a smoother dry film. Use .017 to .019 inch orifice & a 60 mesh screen. If applied with a brush or roller, multiple coats are required to achieve the required thickness. Expect 10-12 mils per coat by brush and 10-12 mils per coat by roller. Use a polyester or polyester/nylon brush. Use a high-quality tapered trim brush with the filament density to achieve a smooth finish on all trim work. Application to a large smooth or any size rough area should be performed with a quality roller cover with a half inch cover to three-quarter inch nap. Regular paint topcoats may be applied over services that have been sprayed, rolled or brushed with LeadClear if desired.

OCCUPANCY DURING APPLICATION: occupancy is permitted during brush or roller application, but not in room or interior area being encapsulated. For spray application, occupancy is prohibited during the day for work site safety reasons only. Occupants may return at the end of the workday.

OCCUPANCY AFTER APPLICATION: Yes. Use adequate ventilation for first 24 hours after application.

CAUTIONS: did you use adequate ventilation. If respiratory irritation develops, increase ventilation or where respiratory protection. Use molded polymesh shell dust and mist respirator – MSHA, NIOSH, Approval No. TC-21C-287 or equivalent during spray application. Avoid contact with eyes and skin. Wash hands thoroughly with soap and water after using. During application wear gloves and safety goggles.

WARRANTY: LeaClear has limited product liability for 20 years. The purchaser shall notify Tara JV Corp. within 30 days after purchase to advise of any assumed manufacturing defects.

CARE AND MAINTENANCE: LeadClear will not protect occupants from ingestion of the encapsulated lead based paint if surface is damaged, broken, or abraded. Surfaces coated with the LeadClear must be inspected routinely for holes, cracks, dents, peeling services, bubbles, or any other defects; including water damage. Damaged surfaces should be repaired and re-encapsulated immediately to prevent exposure to the lead hazard.

REFERENCES:

Deciding whether to encapsulate by Childhood Lead Poisoning Prevention Program.

Register of approved encapsulants by Childhood Lead Poisoning Prevention Program.

Care and maintenance of encapsulants by Childhood Lead Poisoning Prevention Program.

Material safety data sheet (MSDS) by Childhood Lead Poisoning Prevention Program.

LeadClear from Container by Tara JV Corp.

Massachusetts General law (MGL) c. 111, 189A–199B (the Lead Law)

Regulations for Lead Poisoning Prevention and Control 105 CMR 460.000

FOR MORE INFORMATION OR PROBLEM RESOLUTION, CALL:

Tara JV Corp. at 347-538-4591

Childhood lead poisoning prevention program at 1-800-532-9571 or 781-774-6711 (out of state)

The licensed Deleader, who applied the encapsulant. If homeowner or agent applied product, you may wish to call a licensed Deleader for advice or assistance.

Technical Data

Wet Appearance: Milkier Translucent Liquid

Dry Appearance: Translucent

Weight: 8.25-8.75lbs/gal

Specific gravity: 0.99 to 1.050

VOC: Less than 195 GMS/lt.

Dry Time @75 f: 2 – 6 hrs.(Depend upon substrate and weather condition)

Clean up: Water

Solid By Wt.{28fbbca4d5e380ff11c49cfcf258524327390f8bd5020b9c03575f0942ab537b}: 30 – 40 {28fbbca4d5e380ff11c49cfcf258524327390f8bd5020b9c03575f0942ab537b}

Solid By Vol.{28fbbca4d5e380ff11c49cfcf258524327390f8bd5020b9c03575f0942ab537b}: 28 – 38 {28fbbca4d5e380ff11c49cfcf258524327390f8bd5020b9c03575f0942ab537b}

Viscosity: 65 kU Minimum.

Recommended Coat: 2 Coats.

Flash Point: Non Combustible

Shelf life: 2 years

PRODUCT TESTING

ASTM E-1795

ASTM E84

Meets requirements to be utilized as a permanent method for abatement of lead-based paint.

GALLON KIT SIZES

1 & 5